Use ambient air, instead of refrigeration, to provide close temp-erature control of recirculating coolants or oils.

Many R-Closed-Loop or RO-Open-Loop coolers can be supplied with the NRCA option that replaces the standard refrigeration system with an air-to-coolant or air-to-oil heat exchanger. Significant savings can be achieved in both initial and operating cost by using ambient air to control the temperature of coolants being recirculated to your process.

Ambient air must be at least 15°F (9°C) cooler than the lowest desired coolant temperature. Desired coolant temperatures must usually be above 110°F (44°C).

A digital temperature controller cycles a fan moving air across a fin coil heat exchanger to provide close temperature control of recirculating fluids.

All models are supplied with cleanable aluminum air intake filters.

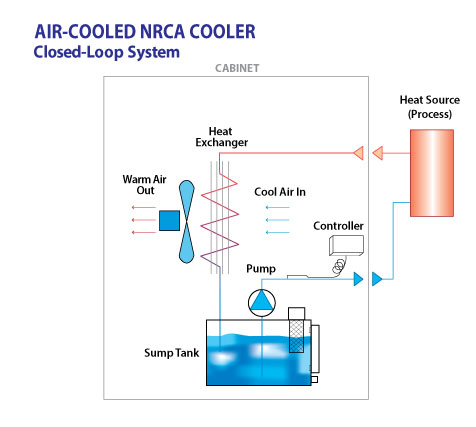

NRCA- Closed Loop Chillers

Closed-Loop coolers recirculate coolant from a tank mounted in the cooler, through a sealed coolant loop and heat load (spindle) and back to the tank. The tank, pump, and evaporator are all in the cooler.

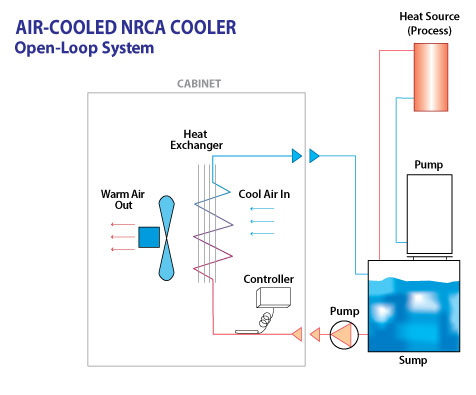

NRCW-Open Loop Chillers

Open-Loop coolers recirculate fluid from a remote tank, through the cooler and back to the tank. The cooler works to maintain a constant fluid temperature in the tank. The pump and evaporator are in the cooler. The tank is remote.

Chilled water must be at least 10°F (6°C) colder than the lowest desired coolant temperature and have adequate flow and pressure for the application. Consult Turmoil for requirements.

Options & Accessories

CTC: Digital Temperature Controller. Provides close temperature control (±0.5°F). Displays bot set-point and coolant temperature.

ATC: Ambient Tracking Controller. A dual input digital temperature controller allows the coolant temperature to track ambient temperature at a constant, adjustable differential. Displays both ambient and coolant temperature.

OP: Optional Pumps. A variety of pumps are available to meet almost any flow and pressure requirement for both water and oil-based coolants.

LF: Low Flow Interlock. Prevents damage to machine on loss of flow.

HT: Temperature Fault Interlock. Indicates coolant temperature is out of range.

LL: Low Level Interlock. Indicates coolant level is low.

FSM: Flow Meter/Switch. Adjusts coolant flow to optimum setting.

ILH: In-Line Heater. Warms up coolant to optimum operating termperature.

ILF: In-Line Filter Insures clean coolant.

PS: Pure System. Coolant only comes in contact with stainless steel or plastic.

RC: Rubber Casters available on all models for complete mobility.

PG: Pressure Gauge available for Discharge and/or Input.