OC Models for Water or Water-Based Coolants including de-ionized water, water/glycol mixtures, and water-based synthetic coolants. Evaporators are brazed, stainless steel plates. Piping and fittings are non-ferrous. Self-priming, bronze, centrifugal pumps are standard. Coolant recirculating through the cooler must be clean, otherwise specify optional In-Line Filter (ILF) or Cleanable Evaporator (CEV).

Model Selection Chart

NOTE: This information is being presented as a guideline only. Your specific application, options and requested features may alter the specifications. Please confirm all specifications with Turmoil.

| MODEL |

RATED COOLING CAPACITY* |

COMP. |

STANDARD PUMP CAPACITY |

STANDARD VOLTAGE** |

| WATER |

BTU/hr |

Kcal/hr |

hp |

gpm |

lpm |

|

| OC-25RO |

3000 |

625 |

1/4 |

1.6 |

6 |

V1, V3 |

| OC-33RO |

4000 |

825 |

1/3 |

1.6 |

6 |

V1, V3 |

| OC-50RO |

6000 |

1500 |

1/2 |

2.5 |

9 |

V1, V3 |

| OC-75RO |

9000 |

2000 |

3/4 |

4 |

15 |

V1, V3 |

| OC-100RO |

12000 |

3000 |

1 |

6 |

23 |

V2, V3 |

| OC-150RO |

18000 |

4500 |

1 1/2 |

8 |

30 |

V6, V8, V10 |

| OC-200RO |

24000 |

6000 |

2 |

8 |

30 |

V6, V8, V10 |

| OC-300RO |

36000 |

9000 |

3 |

12 |

45 |

V6, V8, V10 |

| OC-400RO |

48000 |

12000 |

4 |

16 |

60 |

V6, V8, V10 |

| OC-500RO |

60000 |

15000 |

5 |

20 |

75 |

V6, V8, V10 |

| OC-750RO |

90000 |

22500 |

7 1/2 |

30 |

112 |

V6, V8 |

| OC-1000RO |

120000 |

30000 |

10 |

40 |

150 |

V6, V8 |

| OC-1500RO |

180000 |

45000 |

15 |

60 |

225 |

V6, V8 |

| OC-2000RO |

24000 |

60000 |

20 |

80 |

300 |

V6, V8 |

| OC-2500RO |

300000 |

75000 |

25 |

100 |

375 |

V6, V8 |

| OC-3000RO |

360000 |

90000 |

30 |

120 |

450 |

V6, V8 |

*Capacities based on coolng water to 60°F (16°C) in a 90°F (32°C) ambient.

**Refer to chart below.

Please download our catalog or contact us for full specifications.

| STANDARD VOLTAGE |

| V0 |

100/50/1 |

| V1 |

115/60/1 |

| V2 |

200/50/1 |

| V3 |

208-230/60/1 |

| V4 |

208-230/60/1, 200/50/1 |

| V5 |

200-240/50/3 |

| V6 |

208-230/60/3 |

| V7 |

380-420/50/3, 460/60/3 |

| V8 |

460/60/3 |

| V9 |

575/60/3 |

| V10 |

200-240/50/3, 208-230/60/3 |

| VC |

Custom Voltage

Contact our engineers for more information. |

OCO Models for Oil or Oil-Based Coolants. Evaporators are brazed, enhanced stainless steel plates. Piping and fittings are copper, bronze, steel, or hose. Self-priming, cast-iron gear pumps are standard. Oil recirculating through the cooler must be clean, otherwise specify optional In-Line Filter (ILF) or Cleanable Heat Exchanger (CHX).

Model Selection Chart

NOTE: This information is being presented as a guideline only. Your specific application, options and requested features may alter the specifications. Please confirm all specifications with Turmoil.

| MODEL |

RATED COOLING CAPACITY* |

COMP. |

STANDARD PUMP CAPACITY |

STANDARD VOLTAGE** |

| OIL |

BTU/hr |

Kcal/hr |

hp |

gpm |

lpm |

|

| OCO-25RO |

3000 |

625 |

1/4 |

1.5 |

5.6 |

V1, V3 |

| OCO-33RO |

4000 |

825 |

1/3 |

1.5 |

5.6 |

V1, V3 |

| OCO-50RO |

6000 |

1500 |

1/2 |

2.5 |

9.5 |

V1, V3 |

| OCO-75RO |

9000 |

2000 |

3/4 |

5 |

19 |

V1, V3 |

| OCO-100RO |

12000 |

3000 |

1 |

8 |

30 |

V2, V3 |

| OCO-150RO |

18000 |

45000 |

1 1/2 |

8 |

30 |

V6, V8, V10 |

| OCO-200RO |

24000 |

6000 |

2 |

12 |

45 |

V6, V8, V10 |

| OCO-300RO |

36000 |

9000 |

3 |

18 |

68 |

V6, V8, V10 |

| OCO-400RO |

48000 |

12000 |

4 |

24 |

90 |

V6, V8, V10 |

| OCO-500RO |

60000 |

15000 |

5 |

30 |

112 |

V6, V8, V10 |

| OCO-750RO |

90000 |

22500 |

7 1/2 |

40 |

150 |

V6, V8 |

| OCO-1000RO |

120000 |

30000 |

10 |

50 |

190 |

V6, V8 |

| OCO-1500RO |

180000 |

45000 |

15 |

75 |

280 |

V6, V8 |

| OCO-2000RO |

24000 |

60000 |

20 |

100 |

375 |

V6, V8 |

| OCO-2500RO |

300000 |

75000 |

25 |

125 |

470 |

V6, V8 |

| OCO-3000RO |

360000 |

90000 |

30 |

150 |

560 |

V6, V8 |

*Capacities based on coolng oil to 80°F (28°C) in a 90°F (32°C) ambient.

**Refer to chart below.

Please download our catalog or contact us for full specifications.

| STANDARD VOLTAGE |

| V0 |

100/50/1 |

| V1 |

115/60/1 |

| V2 |

200/50/1 |

| V3 |

208-230/60/1 |

| V4 |

208-230/60/1, 200/50/1 |

| V5 |

200-240/50/3 |

| V6 |

208-230/60/3 |

| V7 |

380-420/50/3, 460/60/3 |

| V8 |

460/60/3 |

| V9 |

575/60/3 |

| V10 |

200-240/50/3, 208-230/60/3 |

| VC |

Custom Voltage

Contact our engineers for more information. |

Click image for larger view.

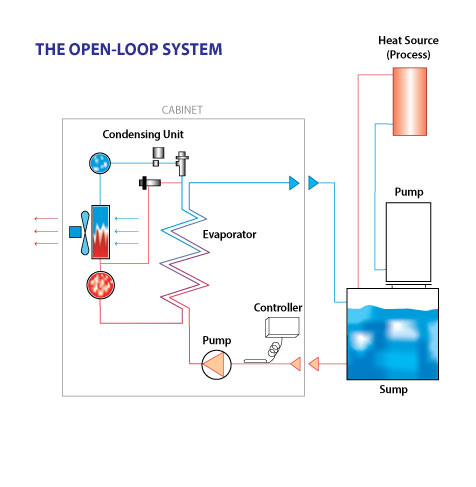

Open-Loop coolers recirculate fluid from a remote tank, through the cooler and back to the tank. The cooler works to maintain a constant fluid temperature in the tank. The pump and evaporator are in the cooler. The tank is remote.

When the pump is energized it draws fluid from the remote tank and pumps it through the evaporator in the cooler and back to the tank. The temperature controller senses the temperature of the fluid entering the cooler and controls the refrigeration effect in the evaporator to provide the desired fluid temperature in the tank. The cooler should be installed as near as possible to the tank.